Work on major high voltage components has started, with both the Vacuum Circuit Breaker and the High Voltage Cable assembly that connects the roof mounted equipment to the transformer being removed for overhaul by Alstom and Mekufa respectively.

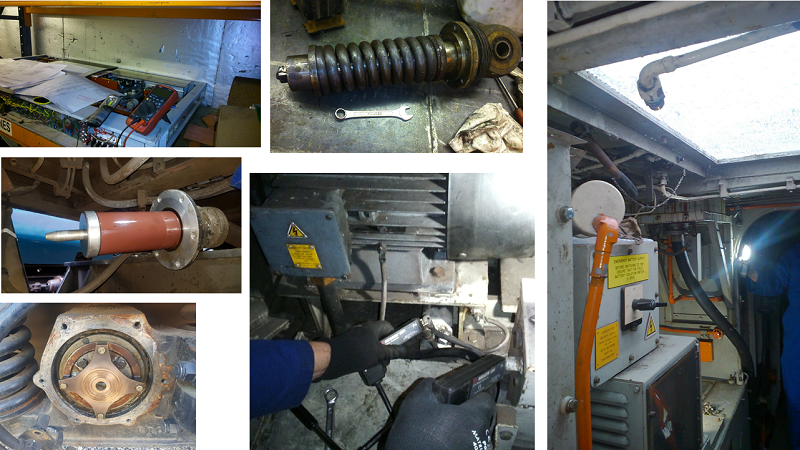

Synthetic electrical testing of the locomotive’s traction circuits has been completed with the functions the Armature Convertors, Power-Brake Thyristors and various contactors having been fully tested. Once testing was completed the Auxiliary Transformers and chokes used to power the locomotive’s control systems were removed for overhaul at Bowers.

Oil sampling has been undertaken on the main Transformer and the Armatures Convertors; in all cases the results indicate that the oil is in good condition.

A considerable amount of time is being spent on inspecting and testing the Earth Bonding and Traction Return cables on the 89; the resistance and mechanical joints of each cable needing to be tested. The six Traction Return Units fitted to the axle box ends have been inspected and cleaned, with re-machining being necessary for two of the axle end ‘spiders’.

The replacement/overhaul of some electronic components is requiring considerable amounts of specialist knowledge, the Field Convertors being the principle area of concern. Some devices are being replaced as they have been identified as being either unreliable or are no longer compatible with variations in the transmission voltage of the railway network; the armature Voltage Measuring Devices are an example of the former and some capacitors in the Surge Suppression Network the latter.

The rebuilding of the rheostatic brake stacks is advancing well with trials of a mechanical mock-up being recently completed. New mountings will now be designed and installed into the locomotive body and the assembly of the two rheostatic brake stacks completed. Replacements for the damaged resistor elements in brake stack #2 have been obtained from Cressall.

On the bogies preparations are being made to replace the axle bearings; specialist tooling has been designed and manufactured to enable the old bearings to be removed and the new bearings installed. The dampers are in the process of being overhauled by Sabre Rail, some of the dampers are unusual and an amount of research has had to be made to determine some of the damper sub-components. The preload units that ‘steer’ axles #1, #3, #4 and #6 have been removed from their respective motors and are in the process of cleaned and refurbished prior to reinstallation on to the overhauled Traction Motors.

The overhaul of Traction Motors #4-6 is nearing completion. The Traction Motors will be reinstalled once the locomotive is lifted for other bogie overhaul work.

Our thanks to our volunteers for their work and to our industry partners at Bowers Electrical, Bralesford Engineering Services and HNRC without whose help the restoration of the 89 would not be possible.